Hospitales de Madrid Prueban Impresoras 3D para Fabricación de Prótesis Personalizadas

Introduction

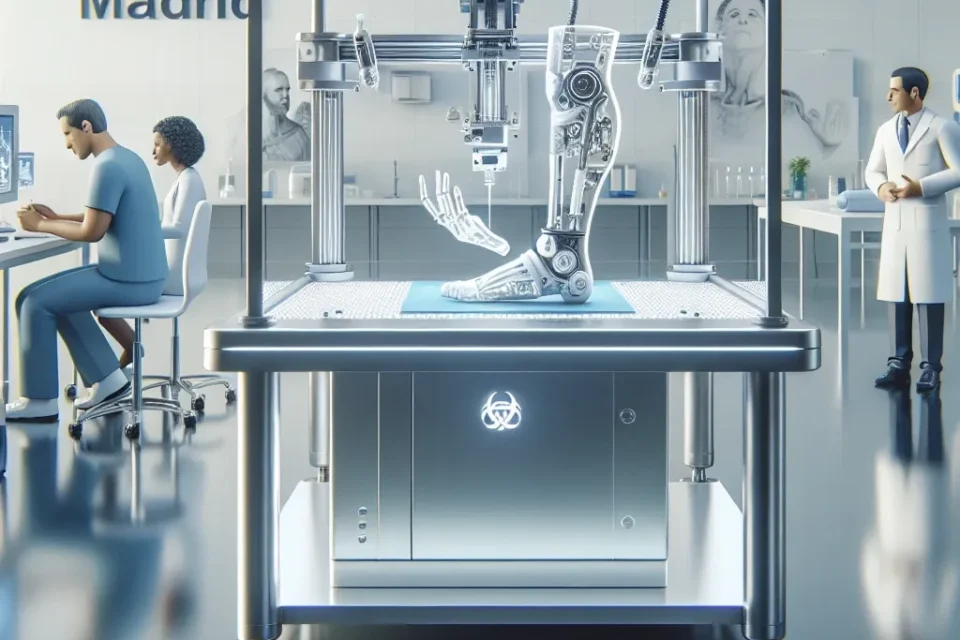

The advancement of technology has made significant strides in the medical field, particularly in the fabrication of prosthetics. Recently, hospitals in Madrid have begun testing 3D printers to create personalized prostheses, marking a transformative step in patient care. This article delves into the implications of this innovation, exploring its historical context, current applications, and future potential.

Historical Context

3D printing, also known as additive manufacturing, has been around since the 1980s. However, its application in the medical field is a more recent development. The ability to produce customized medical devices has opened new avenues for patient-specific treatments. In the past, prosthetics were often generic and required significant adjustments. Now, with 3D printing, hospitals can create bespoke solutions tailored to individual anatomical needs.

Current Applications in Madrid

Several hospitals in Madrid are at the forefront of utilizing 3D printing technology for prosthetics. Hospital Universitario La Paz and Hospital 12 de Octubre are leading the charge by integrating 3D printers into their fabrication processes. These hospitals aim to produce high-quality, customized prosthetic limbs that enhance the quality of life for amputees.

Advantages of 3D Printed Prosthetics

- Customization: One of the most significant benefits is the ability to tailor prosthetics to fit the unique anatomy of each patient.

- Reduced Costs: Traditional prosthetics can be expensive and time-consuming to produce. 3D printing can lower costs and expedite production times.

- Improved Comfort: Custom-fit prosthetics are more comfortable for users, leading to better usability and satisfaction.

- Rapid Prototyping: 3D printing allows for quick iterations, enabling hospitals to refine prosthetic designs based on patient feedback.

Step-by-Step Process of 3D Printed Prosthetic Fabrication

1. Patient Assessment

The process begins with a thorough assessment of the patient, which includes imaging and modeling of the limb or body part needing the prosthetic.

2. Digital Design

Using advanced software, medical professionals create a 3D model of the prosthetic tailored to the patient’s specific measurements.

3. 3D Printing

The custom design is then sent to a 3D printer, where the prosthetic is fabricated layer by layer using biocompatible materials.

4. Fitting and Adjustments

After printing, the prosthetic is fitted to the patient, and adjustments are made as necessary to ensure optimal comfort and functionality.

Challenges and Considerations

While the benefits of 3D printing for prosthetics are significant, there are also challenges to consider:

- Regulatory Approval: New technologies must undergo stringent testing and approval processes before they can be widely used.

- Material Limitations: Not all materials are suitable for prosthetic fabrication; ongoing research is needed to find optimal solutions.

- Training and Expertise: Medical staff must be trained in both the technology and the design processes to ensure successful implementation.

Future Predictions

The future of 3D printed prosthetics looks promising. As technology advances, we can expect:

- Enhanced Materials: Continued research may lead to new materials that are lighter, stronger, and more biocompatible.

- Wider Accessibility: As costs decrease, more hospitals globally may adopt this technology, providing better access to personalized prosthetics.

- Integration with AI: Artificial intelligence could play a role in further customizing prosthetics based on real-time data from patients.

Cultural Relevance

In Spain, the move towards personalized medicine reflects a larger trend towards patient-centered care. By harnessing 3D printing technology, hospitals in Madrid are not just enhancing medical treatments but also promoting dignity and independence for individuals with limb loss. The cultural implications are immense, as society increasingly recognizes the importance of tailored healthcare solutions.

Expert Opinions

Dr. Carlos Martinez, a leading specialist in orthopedics at Hospital Universitario La Paz, states, «The integration of 3D printing into our workflow is a game-changer. It allows us to provide our patients with prosthetics that not only fit better but also empower them to lead more fulfilling lives.»

Conclusion

The trials of 3D printers in hospitals across Madrid herald a new era in the creation of personalized prosthetics. With the potential to revolutionize patient care, this technology offers a glimpse into the future of medicine where customization is not just a luxury but a standard. As hospitals continue to innovate and adopt 3D printing, the hope for improved quality of life for amputees is brighter than ever.